Key features

- Quickly locates opens, shorts, and high-voltage shorts

- Fully automated operation

- Simple, guided testing

- 6-inch colour TFT touchscreen display

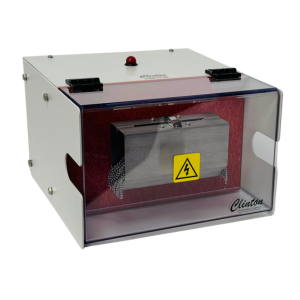

- Compact, lightweight unit

- CE approved

Easy testing

To test a cable the operator connects the FL-20A test probes to each end of the of the cable, enters the cable length and selects shorts or opens to start testing. The unit calculates the distance of the faulty from the test probe and displays the fault location in metres and provides a suggested trim area. The fault can then be cut out or repaired and the remaining good cable salvaged, resulting in a reduced scrap and better yield for the cable manufacturer.

Why choose the FL-20A?

- Fully automated testing — no manual meter adjustments or calculations required.

- Fast, accurate distance-to-fault results from both ends of the cable, displayed in feet or metres.

- Minimises waste and costly scrap by allowing only the damaged section to be cut out or repaired.

- Simple to operate via colour touchscreen, reducing reliance on skilled fault-finding technicians.

- Compact and lightweight, designed for production-floor use and easy movement between lines.

- Supported locally by Control Metrix’s measurement specialists for seamless installation, calibration, and support

Support from Control Metrix

As the exclusive distributor for Clinton Instrument Company in the UK and Ireland, Control Metrix supplies FL-20A systems with full application guidance, commissioning support, and after-sales service. If you’re struggling with costly scrap or slow fault location on multi-conductor cables, we’ll help you integrate the FL-20A into your QC workflow and maximise yield.

Talk to us

Want to reduce scrap and speed up fault location on your cable line?

Contact our team to discuss your application, request pricing, or arrange a consultation.