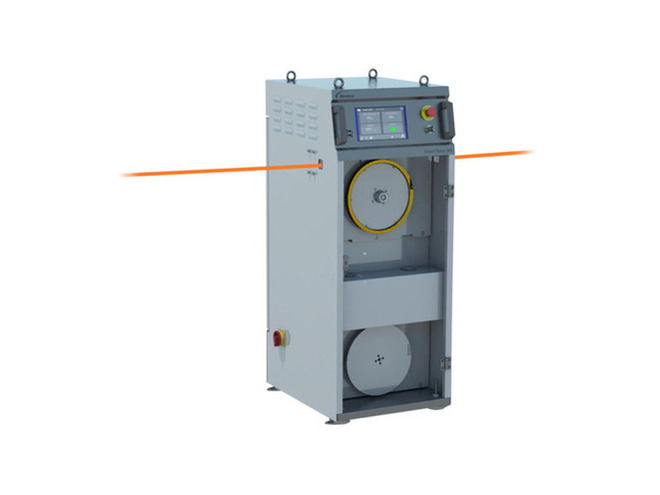

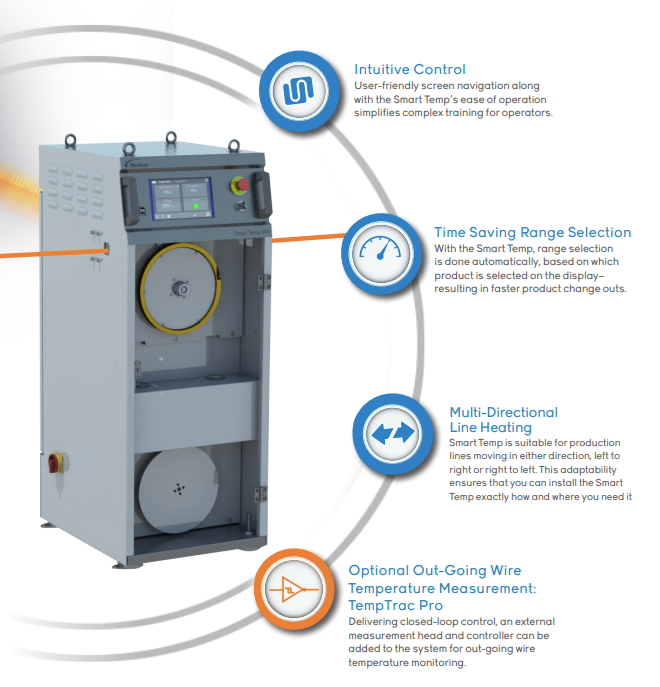

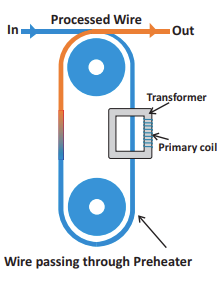

Beta LaserMike wire preheaters ensure consistent and stable preheating in cable production is paramount to producing high-quality product that is fit for purpose and reduces waste. By precisely controlling the wire temperature, the Smart Temp 280 helps to mitigate risks such as cracks and thermal shock, or inconsistent insulation application, ultimately enabling optimal cable production. This system ensures efficient energy transfer to pre-heat the wire uniformly through intelligent automatic range selection.

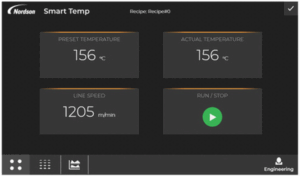

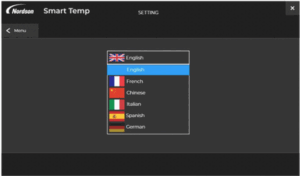

Intuitive and precise control is facilitated by the user-friendly, 10-inch touchscreen communication system. Setting up and controlling the system is now more efficient than ever thanks to the intuitive menus, functions, and settings, streamlining setup procedures, reducing training requirements, and accelerating product changeovers through integrated recipe management.

The Smart Temp 280 offers versatile performance with: multidirectional line heating, allowing for flexible setup in lines running in either direction (left-to-right or right-to-left); a wide wire diameter range; and the capability to handle high line speeds. Furthermore, its robust design with IP53-rated protection ensures reliable operation in demanding industrial environments.

Optional integration of the TempTrac Pro temperature measurement system provides precise, closed-loop temperature control, further enhancing process stability and product quality. The Smart Temp 280’s standard communication interfaces (including options such as Profibus and Ethernet) ensure seamless integration into existing industrial control architectures, making it a reliable partner for achieving superior process efficiency, reduced waste, and enhanced product quality in your industrial applications.