Advanced Non-Contact Solutions for Packaging Integrity and Process Control

Skip to products

In the highly regulated pharmaceutical and medical sectors, ensuring product safety, packaging integrity, and regulatory compliance is non-negotiable. At Control Metrix, we deliver state-of-the-art non-contact measurement solutions designed specifically to support pharmaceutical manufacturers, medical device producers, and packaging specialists.

Our advanced moisture measurement systems, seal integrity testing equipment, and non-destructive leak detection technologies provide critical support for sterile and modified atmosphere packaging applications, offering real-time insight into in-process conditions and packaging performance. These tools help companies maintain quality, prevent contamination, and protect brand reputation.

In the pharmaceutical and medical industry, the moisture content levels in products need to be precisely controlled throughout the manufacturing process. Our systems will provide the next level of process control, helping you to improve efficiency and allowing you to take swift corrective actions leading to a better-quality end product and reassurance for your customers.

Our NIR non-contact moisture gauges and at-line analyzers are perfect for applications in the pharmaceutical industry, including real-time moisture content analysis during the production of powders, flakes and slurries. Using a sapphire sight glass, the instrument takes real-time measurements during the drying process within a fluid bed dryer, ideal as part of your Process Analytical Technology (PAT) strategy.

Get in touch to discuss the ideal moisture measurement solution for your production line. Call: +44 (0)1823 761 309 or complete the enquiry form and we’ll get back to you.

Pharmaceutical & Medical Products

In the manufacturing of intravenous tubes, catheters and other medical tubes, strict regulation demands of product quality and tight dimensional tolerances and clean-process environments are non-negotiable. Laser micrometer systems deliver non-contact, high-speed and ultra-accurate diameter measurement. Combined with the TrueWall (formerly UltraScan Pro), ultrasonic wall thickness measurement will provide complete product measurement and dimensional control. Typical applications include medical tubes and catheters, micro-precision implants, and high-volume extruded parts where in-process monitoring can immediately detect variations and prevent out-of-spec production.

By integrating laser micrometers into the production line, manufacturers can shift from sample-based checks to continuous online measurement and feedback. This means defects are caught in real-time, process drift is minimised and corrective action can be automated or triggered faster, helping maintain regulatory compliance in cleanrooms, reduce costly scrap or rework and improve yield. Because the measurement is non-contact, even delicate or moving components can be measured reliably without risk of damage or contamination.

Discover how laser micrometers can transform your production accuracy and efficiency. Call us to speak with a product expert: +44 (0)1823 761 309 or complete the enquiry form and we’ll get back to you.

Control Metrix offers two trusted technologies to evaluate the quality and reliability of pharmaceutical and medical packaging:

- Bubble Emission Testing

The Dynascan LeakVIEW system provides visual confirmation of packaging leaks by immersing the product in a water-filled vacuum chamber. Under reduced pressure, even microscopic leaks become visible as escaping bubbles. This intuitive method is ideal for rapid QA testing in production environments where packaging failures must be detected immediately.

- Vacuum Decay Leak Detection

The Sealtick TSE 6086b system delivers non-destructive, repeatable results via vacuum decay technology. It accurately measures packaging seal integrity without compromising sterile barrier properties. Designed for the pharmaceutical and medical device industries, the Sealtick device ensures compliance with GMP, ISO 11607, and other quality standards.

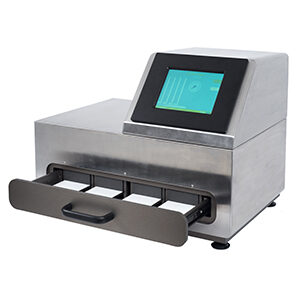

- High-Sensitivity Vacuum Decay Tester

The Dynascan MediTEST is engineered for stringent environments, it delivers highly repeatable vacuum decay testing for medical, pharmaceutical, and food packaging. It supports method development, automated testing, and full data traceability – ensuring audit-readiness and consistent QA control.

- Blue Dye Ingress Testing System

The Dynascan MediBLUE employs the dye ingress method. It enables visual inspection of packaging for seal breaches using a low-viscosity blue dye, ideal for pharma and medical device applications where transparent packaging verification is required.

Why It Matters

- Prevents microbial contamination and oxygen/moisture ingress

- Supports shelf life validation and regulatory audits

- Reduces product recalls and cost-intensive quality failures

Designed for Cleanroom & GMP Compliance

Our seal integrity systems are engineered with hygienic design principles and can be operated in cleanroom environments. Whether you’re manufacturing blister packs, syringes, pouches, or medical trays, we offer measurement equipment that integrates seamlessly into existing QA workflows while upholding compliance with MHRA, FDA, and EMA regulations.

Key Applications:

- Sterile pharmaceutical packaging (e.g. vials, ampoules, blister packs)

- Medical device packaging (e.g. implant trays, surgical kits)

- Modified atmosphere packaging (MAP) for drug delivery systems

We also supply fiber optic temperature sensing equipment for medical research, general research and development, and OEM applications.

Typical applications include:

- MRI and RF Medical Treatment

- Pace Makers and Implantable Device Testing

- Temperature Monitoring of Critical Military Equipment and Facilities

- Temperature Control of Microwave Processes

- Monitoring of Semiconductor Wafer Temperatures During RF and

- Plasma Applications

Full-Spectrum Support from Concept to Compliance

From initial consultation through qualification and aftercare, Control Metrix provides complete lifecycle support:

- Product consultation & specification advice

- IQ/OQ documentation and validation testing

- Operator training and commissioning

- Routine maintenance and calibration services

Our UK-based specialists ensure your project remains on track, compliant, and performance-optimised.

Contact Control Metrix Today

Arrange a consultation with a product expert to explore how our pharmaceutical-grade leak detection and seal testing systems, moisture and temperature control can support your production and compliance goals.

Call: +44 (0)1823 761 309 or

Email: hello@control-metrix.com

Control Metrix – Measurement Excellence

ISO 9001:2015 Certified

We adhere to strict quality standards to ensure that all equipment, support, and processes meet international quality management requirements.

________________________________________

Explore Our Knowledge Hub For More Information