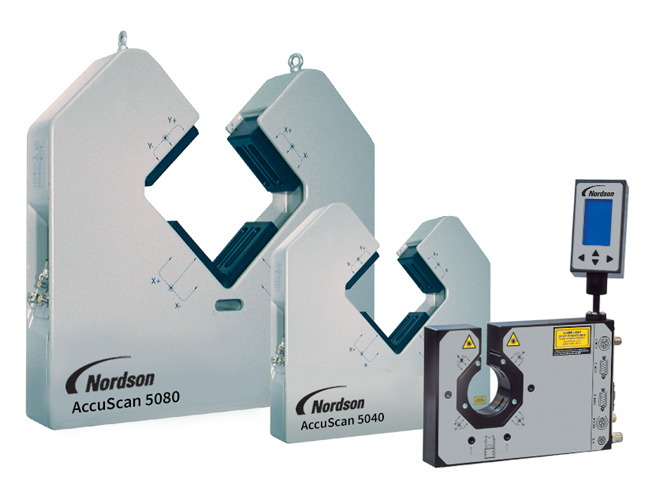

AccuScan Pro In-process Measurement Laser Micrometers

AccuScan single-axis, dual-axis and quad-axis gauges are designed for use in cable and wire and extrusion and hose or many other types of industries where it is important to precisely measure diameter, ovality and detect flaws of round products as they are being manufactured. When used together with DataPro process controller will provide real-time process monitoring statistical reporting and automated process control.

BenchMike Pro & Z-Mike Pro Offline or Benchtop Laser Micrometers

The industry leading benchtop micrometers for absolute precision in non-contact measurement of round and cylindrical shaped components. These gauges are designed for at-line or inspection room use for sample inspection. The BenchMike Pro provides exceptional accuracy and speed of measurement yet is easy to use. A comprehensive range of fixturing and tooling is available including motorised chuck to ensure accurate part presentation and repeatable measurement. Dedicated fixturing to measure the ID, OD and wall thickness of medical and plastic tubes is also an option. For ultimate accuracy, the Z-Mike Pro model offers unmatched measurement performance when measuring precision machined components such as fuel injectors, cutting tools medical devices, shafts and other cylindrical shaped components. In addition to diameter, the BenchMike Pro will also measure ovality, taper, TIR, runout and effective diameter on cutting tools.

Smart Temp 280 Wire Preheater

As well as diameter and ovality measurement, precise temperature control is essential for wire cable production to prevent cracking and inconsistencies. The Smart Temp 280 wire preheater offers consistent and stable preheating, regardless of line speed or direction, to prevent waste and ensure a high-quality finished product. With an intuitive 10-inch touchscreen, menus, automatic range selection, and a robust design, the Smart Temp 280 is a must for process efficiencies and retaining high production standards.

Our strategic partnerships with industry-leading suppliers enable us to deliver premium quality, cost-effective laser micrometer solutions built for your specific applications. Leveraging decades of experience supporting customers across the UK and Ireland, and a proven track record with manufacturers like yours, we are uniquely positioned to identify the ideal measurement technology for your precise requirements.

Support services

Beyond equipment supply and installation, our comprehensive service includes commissioning, field servicing calibration, operator training, and ongoing technical support across the UK and Ireland to ensure long-term system performance.

Laser Micrometer Products