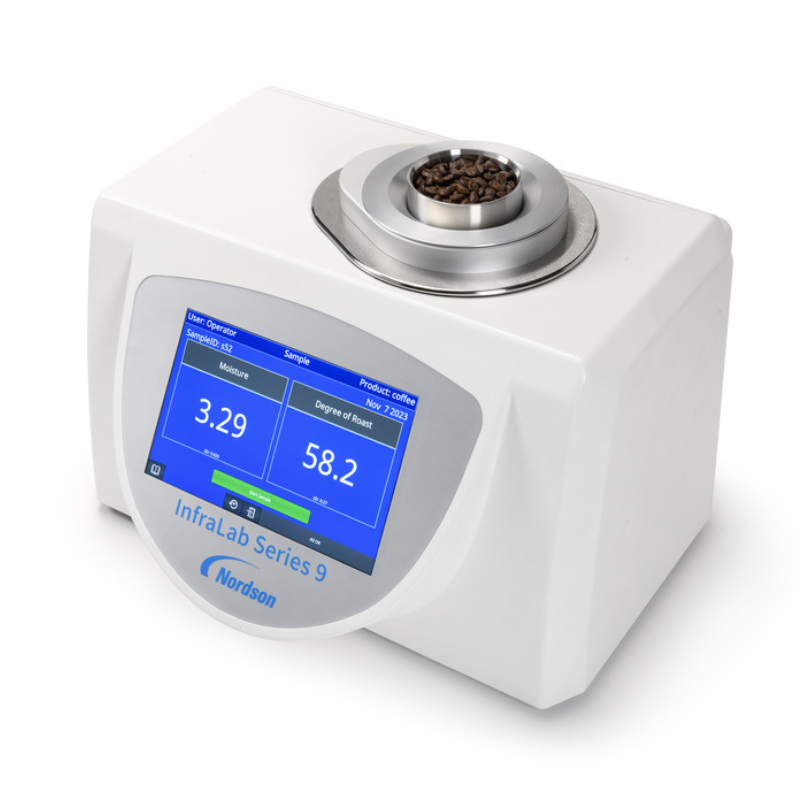

The InfraLab Series 9 Top Loader is the latest advancement in Nordson’s NIR technology lineup – purpose-built for at-line or lab-based analysis of powders, grains, and semi-solid products. Offering ultra-fast measurement times – under five seconds – it now integrates advanced colorimetric assessment alongside moisture, fat, and protein quantification.

InfraLab Series 9 Top Loader Analyzer

InfraLab Top Loader Analyzer

Enquire Now

"*" indicates required fields

Overview

Engineered to support continuous process improvement in food and ingredient manufacturing, the Series 9 Top Loader delivers multi-component analysis with high precision. Unlike traditional laboratory methods, it requires no chemicals, drying, or lengthy prep—enabling manufacturers to get real-time insights without interrupting production.

This model is ideal for:

-

Fine powders and granular materials

-

Semi-solids and compressed sheets

-

Coffee, dairy, cereals, and snack applications

Incorporating next-generation optics and intelligent signal processing, the analyzer outputs rapid readings for key attributes like moisture, protein, and fat content. Built-in memory allows storage of results for further QA review and integration with data management systems.

Operating Principle

Consistent Results via Precision Sample Handling

One of the Top Loader’s standout features is its sapphire-based sample container. This ensures the product is presented consistently, flatly, and without interference from surface irregularities – minimizing measurement variation. This results in exceptionally repeatable outputs, regardless of environmental fluctuations such as temperature or humidity.

Advanced Optical Analysis

The InfraLab operates on a refined near-infrared transmission principle. By targeting specific absorption bands associated with moisture, protein, and oil, the device calculates precise content levels using proprietary algorithms calibrated to your product type. Notably, the system is robust against external factors like particle size changes or ambient lighting – ensuring confidence in every reading.

The colour analysis function outputs industry-standard metrics, including CIE Lab* values, helping manufacturers maintain visual consistency and meet customer expectations for appearance.

Applications

- Bakery

- Breakfast Cereals

- Cheese Processing

- Coffee

- Cocoa Bean Processing

- Confectionery

- Dairy Products

- Ingredients

- Rice & Noodles

- Pharmaceuticals

- Starch Processing

- Sugar Processing

InfraLab Top Loader Analyzer:

The InfraLab Top Loader is the latest at-line analyzer that can measure single or multi-component elements that replaces expensive and slower traditional laboratory testing methods.

Easy-to-use, the InfraLab Top Loader Analyzer requires no special operator skills and takes just five seconds to make the analysis. Using multi-wavelength NIR reflection, the Top Loader does not require contact with the product sample. The sapphire-based sample pot is placed on the turntable at the top of the machine and the analysis begins.

The InfraLab Top Loader Analyzer has its own substantial onboard data storage capacity (up to 100,000 sample files), but data can also be downloaded periodically to a USB memory stick or directly to a PC for analysis in a spreadsheet or other software. Alternatively, it connects via Ethernet to a PC where the data is stored and displayed and can also be integrated into a LIMS network.

Other features include

- User-configurable multi-lingual interface

- Passcode protection with various user access levels

- Barcode scanner to easily select recipes

- Ethernet and LIMS connectivity

- On-board storage of over 100,000 sample files with instant access to historical data with USB that exports .CSV to Excel.

Quick Spec

| Moisture Range | Oil Range | Colour | Measuring Principle |

| 0-80 % | 20-45% | CIELAB, XYZ and Degree of Roast in Coffee | NIR |

What our customers say…

|

As a manufacturer of various snacks and crisps it is very important for us that we have the ability to measure and control the moisture and oil content as both can dramatically affect product quality, shelf-life and ultimately our reputation. Traditionally, we have always relied on established moisture balance and Carver press methods, but these methods can prove to be very time-consuming. We now favour the NDC Technologies’ InfraLab food analyzer, which has revolutionised our quality checks by making them faster and more frequent. We have found the InfraLab very easy to use and we have found the ability to keep data for quality audits invaluable. We have always been very impressed with Kevin Goodison at Control Metrix’s level of service and we have appreciated him taking the time to visit us and assist us with new technologies and training etc.

Shahid Iqbal – QC Manager, Kolak Snack Foods |

|

Kevin’s industry experience and product knowledge were evident and it has been great to have one point of contact throughout the process. Kevin even wrote our standard operating procedure (SOP) for us, which was much appreciated. We have been using the InfraLab Food Analyzer for ten months now and we can honestly say that there has been a massive improvement in our production processes and ultimately the quality of the end product. The potato waffles are now the crispiest that they have ever been and are now Birds Eye’s star product, thanks to the Infralab Food Analyzer and the guidance and support provided by Control Metrix.

Nigel Jackson – Process Technologist, Birds Eye |