“The reliability and accuracy of the moisture gauges are never in doubt and we have relied upon them for many years. Kevin and his team have always been on hand to ensure we achieve the best out of our equipment.” Read more.

Why Accurate In-Process Measurement Matters – Building Materials Industry

Control Metrix acknowledges the critical importance of consistent and accurate in-process measurement systems for manufacturers in the building materials sector, ensuring sustained operational reliability. Recognizing the continuous (24/7) nature of many of these plants, our equipment is engineered for prolonged operation in challenging environments with minimal maintenance and recalibration.

With extensive experience spanning many years, Control Metrix has partnered with numerous leading building materials companies worldwide, providing dedicated in-process, non-contact measurement systems that deliver dependable process insights.

Inadequate measurement control during building material production can lead to substantial operational challenges, including increased costs and reduced customer satisfaction, ultimately undermining trust in your company’s reliability and damaging your reputation within the sector.

Control Metrix Expertise in Building Materials Production

Our expertise enables us to implement in-process measurement systems precisely tailored to the unique demands of building materials production. These systems enhance your process control, improve plant efficiency, and facilitate rapid corrective actions, resulting in higher quality products and increased customer confidence.

Through our partnerships with leading industry suppliers, we provide premium quality, cost-effective measurement solutions specifically for the building materials sector. Leveraging our extensive experience and proven success with similar companies, we can guide you to the ideal product for your unique requirements. Furthermore, we offer comprehensive commissioning, training, and ongoing support services.

Applications in Building Materials

Panel Production Lines

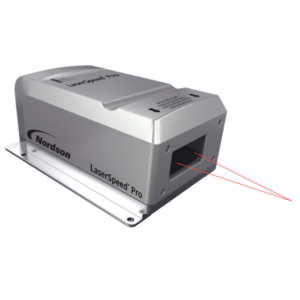

Achieving precise dimensional accuracy is paramount in the production of various panels for the building industry, including insulation boards, cladding panels, particle board, MDF, OSB, cement board, and diverse cladding materials. Our precise non-contact laser length measurement systems provide real-time, high-speed dimensional control throughout the production process. This ensures that panels are cut to exact specifications, minimising material waste from overcuts or rejects due to incorrect sizing. The benefits include:

- Enhanced Cutting Accuracy: Leading to tighter tolerances and improved fit during construction.

- Reduced Material Waste: Optimising raw material usage and lowering production costs.

- Improved Quality Control: Ensuring consistent panel dimensions and reducing the risk of costly errors on-site.

- Increased Production Efficiency: Enabling faster processing speeds with reliable measurement data for automated cutting systems.

- Compliance with Building Standards: Facilitating the production of panels that meet stringent industry regulations and specifications.

Brick, Tile and Aggregates

Consistent moisture content is a critical factor in the manufacturing of high-quality bricks, roofing tiles, and various aggregates like sand and cement mixes. Our advanced non-contact Near-Infrared (NIR) moisture sensors provide continuous, in-process monitoring of these bulk materials. This real-time data allows for precise control of water addition during the mixing and forming stages, leading to significant improvements in the final product. The advantages of our NIR moisture measurement include:

- Optimised Mix Consistency: Ensuring uniform moisture levels throughout the material, leading to consistent product strength and durability.

- Reduced Drying Defects: Preventing cracking, warping, and other defects caused by inconsistent moisture during the drying process.

- Energy Savings: Optimising the drying process by ensuring the material enters the kiln with the ideal moisture content.

- Improved Product Quality: Resulting in bricks, tiles, and aggregates that meet required strength, dimensional accuracy, and aesthetic standards.

- Minimised Waste and Rework: Reducing the number of rejected products due to moisture-related issues.

Building Materials Products

PrediktIR II Bulk Materials Moisture Gauge

The PrediktIR II Bulk Materials Moisture Gauge is a rugged, in-process bulk materials moisture gauge suitable for directly measuring materials including sand, clay, wood chips and cement mix. Using near-infrared (NIR) non-contact technology, it provides accurate and dependable, real-time moisture measurements that can be used to improve process control.

Series 9 Industrial Moisture Gauge

The Series 9 Industrial Moisture Gauge is the latest generation sensor for precise on-line measurement of moisture for almost any material. The gauge is capable of measuring the widest range of materials including powders, coarse or fine particles, concentrates, slurries, pastes, flakes and granules.

Mikron® Thermal Imaging Cameras

Mikron Thermal Imaging Cameras are high-performance IR thermal imaging systems for accurate temperature measurement in a number of dedicated industrial applications including in-furnace temperature mapping.

Thyristor Power Controllers

Thyristor Power Controllers provide efficient, reliable and precise control of electrical heating, which is absolutely essential in many industrial thermal processes including industrial furnaces, IR drying, glass manufacturing, semiconductors, heat treatment, melting, drying and forming.

Enquire Now

Arrange a call with a product specialist to find out how a non-contact measuring system from Control Metrix could benefit your company.

Building Materials Form

"*" indicates required fields

Looking for Something Different?

Our sister company are experts in non-contact dimensional measurement systems for the building industry. Contact us for more information.

What Our Customers Say…

"Regular calibration and servicing are not issues we need to be concerned about as once again, Kevin and the team at Control Metrix are always available to help."

"I was immediately impressed with their expertise"

“I knew that some of the other Wienerberger sites had already purchased some NDC PrediktIR moisture gauges and I had heard that they were really improving the production processes and quality control procedures. I met up with some of the Control Metrix team at ClayTech, and I was immediately impressed with their expertise and what they had to offer. After discussions with NDC Product Specialist, we went ahead and purchased four NDC PrediktIR gauges. The gauges have really helped us to monitor and have greater control of our water input system and we are already getting some really useful data. I would certainly purchase from Control Metrix again in the future.” Read more.

"We were very impressed"

“We got a call from John Miller back in 2018, just as we were finding our existing moisture gauge was failing. We discussed the possibility of replacing our existing gauge with an NDC gauge and invited John to come in for a site visit and to subsequently quote us for a PrediktIR. We were very impressed with John’s product knowledge and we decided to proceed with the purchase. We have found the PrediktIR to be very reliable and we are very happy with it.”

"The customer service and aftersales support was great!"

“We found that we were actually losing a lot of money due to not having the correct moisture content in our bricks, so back in January 2019, we decided to look into implementing some non-contact NIR moisture gauges to enable us to monitor this more effectively. We contacted Control Metrix and installed two NDC Technologies’ PrediktIR moisture gauges in our priority clay prep. area. I am very happy with the PrediktIR gauges and having the ability to constantly monitor the moisture content has massively improved our quality control processes. We were impressed with the evident product knowledge and expertise demonstrated by the team at Control Metrix and the customer service and aftersales support was great!” Read more.

Made to Measure Support Every Step of the Way

We believe our customers should deal with an expert from the point of enquiry to project completion. Therefore, we will appoint you a product specialist, so you have continuity and a single point of contact. They will be your guide, help identify the best solution for your particular application and be with you through to successful implementation.

Arrange a call with a product specialist to find out how Control Metrix could benefit your company.

Call +44 (0)1823 761 309 today.