“When rebuilding one of our clamshell furnaces we opted for four Impac ISR 6 pyrometers for precise temperature measurement. I am very impressed with the quality of every component from the cooling jackets to the sensors themselves, which seem exceptionally well made. I would not hesitate to contact Control Metrix in the future for any other applications that I may need help/equipment for.”

Advanced non-contact sensors and measurement systems

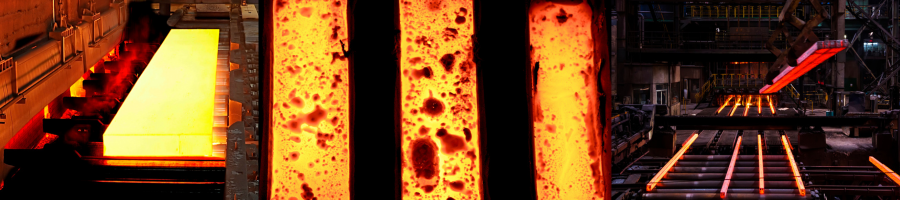

At Control Metrix, we recognise the critical importance of robust, mill-worthy measurement technologies in modern steelmaking and downstream processing. Inadequate in-process measurement can lead to inconsistent product quality, reduced yield, and avoidable inefficiencies. Drawing on many years of industry experience, we supply advanced non-contact sensors and measuring systems designed specifically for the harsh and demanding environments found in steel production. Our portfolio includes laser Doppler speed and length gauges, as well as high-accuracy infrared pyrometers for precise temperature monitoring at every stage of the process. By enabling real-time measurement at essential stages of the manufacturing process, these technologies boost efficiency, consistency, and overall product quality – giving steel producers and finishing lines a clear competitive advantage.

Real-Time Process Measurement

Integrating infrared pyrometers and laser Doppler gauges directly into the production line enables manufacturers to obtain immediate, accurate process feedback. When these measurements are connected to the plant’s SCADA or automation infrastructure, operators gain a comprehensive, real-time overview of all critical parameters. This enhanced visibility supports faster decision-making, improved process control, and greater operational efficiency across the mill.

What we Measure

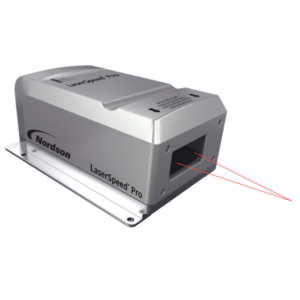

Accurate and Dependable Non-Contact Speed & Length Measurement

Leading steel and aluminium producers worldwide rely on the LaserSpeed Pro for precise, non-contact speed and length measurement. Using proven Laser Doppler Velocimetry (LDV) technology, the system delivers exceptionally high accuracy in determining product velocity and length, even under demanding mill conditions. A full range of models is available to suit virtually any application hot or cold across the entire process, from continuous casting, hot rolling to cold rolling and downstream finishing operations.

Advanced Temperature Measurement

With rising energy costs and increasingly stringent quality requirements, precise temperature control has never been more critical for the steel industry. Control Metrix offers a comprehensive portfolio of high-performance pyrometers and thermal imaging systems designed for accurate, non-contact temperature measurement across every stage of steel production. Drawing on many years of application experience, we specify and supply reliable infrared measurement solutions that provide the stable, repeatable data essential for process optimisation, product consistency, and operational efficiency.

Our Capabilities & Services

We provide far more than measurement hardware, we work as a long-term technical partner to ensure each solution delivers sustained performance and value. Our services include:

- Application specific system specification tailored for your production line

- On-site commissioning and product configuration to ensure accurate and reliable operation.

- Operator training and documentation.

- Ongoing technical support, service contracts and consultancy.

With decades of working experience alongside leading steel producers, we deliver solutions built for longevity, accuracy, and real-world value.

Why Choose Control Metrix?

- High-quality support through specifying, supply, commissioning, training and support through the entire product lifecycle.

- Premium quality products from industry-leading suppliers

- Expert team with deep industry knowledge

Commitment to project support from concept to long-term operation.

Ready to Transform Your Production Line?

Click through to the product information below, use the chat function, or contact our team to discuss your measurement challenges and explore how our integrated systems can elevate your processes.

Metal & Steel Industry Products

Speed & Length Gauges

IR Temperature Measurement Pyrometers and Thermal Imagers

Impac Pyrometers

Mikron® Thermal Imaging Cameras

Mikron Thermal Imaging Cameras are high-performance IR thermal imaging systems for accurate temperature measurement in a number of dedicated industrial applications including in-furnace temperature mapping.

FurnaceSpection™

The FurnaceSpection™ is a radiometrically calibrated thermal imaging system that provides real-time continuous temperature measurement inside high-temperature furnaces in glass production processes.

Power Controllers

Thyristor Power Controllers

Thyristor Power Controllers provide efficient, reliable and precise control of electrical heating, which is absolutely essential in many industrial thermal processes including industrial furnaces, IR drying, glass manufacturing, semiconductors, heat treatment, melting, drying and forming.

Enquire Now

Arrange a call with a product specialist to find out how a non-contact measuring system from Control Metrix could benefit your company.

Enquire Now

Steel Industry Form

"*" indicates required fields

Looking for Something Different?

Our sister company are experts in non-contact dimensional measurement systems for the metals industry. Contact us for more information.

What Our Customers Say…

"I would not hesitate to contact Control Metrix in the future"

Made to Measure Support Every Step of the Way

We believe our customers should deal with an expert from the point of enquiry to project completion. Therefore, we will appoint you a product specialist, so you have continuity and a single point of contact. They will be your guide, help identify the best solution for your particular application and be with you through to successful implementation.

Talk to a UK product specialist to find out how Control Metrix could benefit your company.

Call +44 (0)1823 761 309 today.